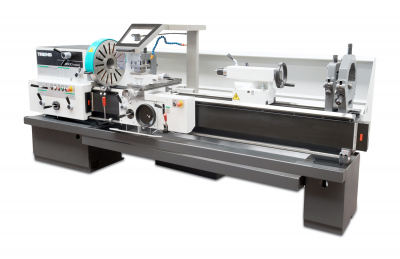

| Swing over bed | 505 mm | |

| Swing over cross slide | 270 mm | |

| Swing in bed gap | 700 mm | |

| Spindle bore | 77/105* mm | |

| Useful lenght in gap from front of spindle nose | 230 mm | |

| Height of centres | 250 mm |

* optional execution

Description

Universal centre lathe SN500 Classic is for piece and small-lot production suitable for maintenance and repair divisions as well. SN 500 classic can be optionally produced in an execution with increased spindle bore of 105 mm. It is customers´ classic with main motor output of 7,5 kW.

Machines of outstanding performance designed for piece and small-lot production suitable also for maintenance and repair divisions. TRENS lathes are precise and reliable machines in wide range of versions and optional accessories.

Main characteristic features:

- Simple and ergonomic control

- Hand scraping of important parts - high precision during machining

- Long life time

- Low operating costs

- Easy maintenance

- Possibility to cut various types of threads with wide range of pitches

- Reversing lever for apron direction movement during thread cutting - more comfortable thread cutting

Characteristic features

Universal centre lathes belong to the most requested products of production portfolio of company TRENS SK, a.s.. Since half of the twentieth century they were known under the brand TOS (currently TRENS) and are still fulfilling the highest customers´ requirements.

Thanks to persistent quality and sustaining development TRENS SK reaches leading places among world producers of universal center lathes. The result is more than 500 000 sold lathes throughout the globe and satisfied customers that repeatedly choose brand TRENS.

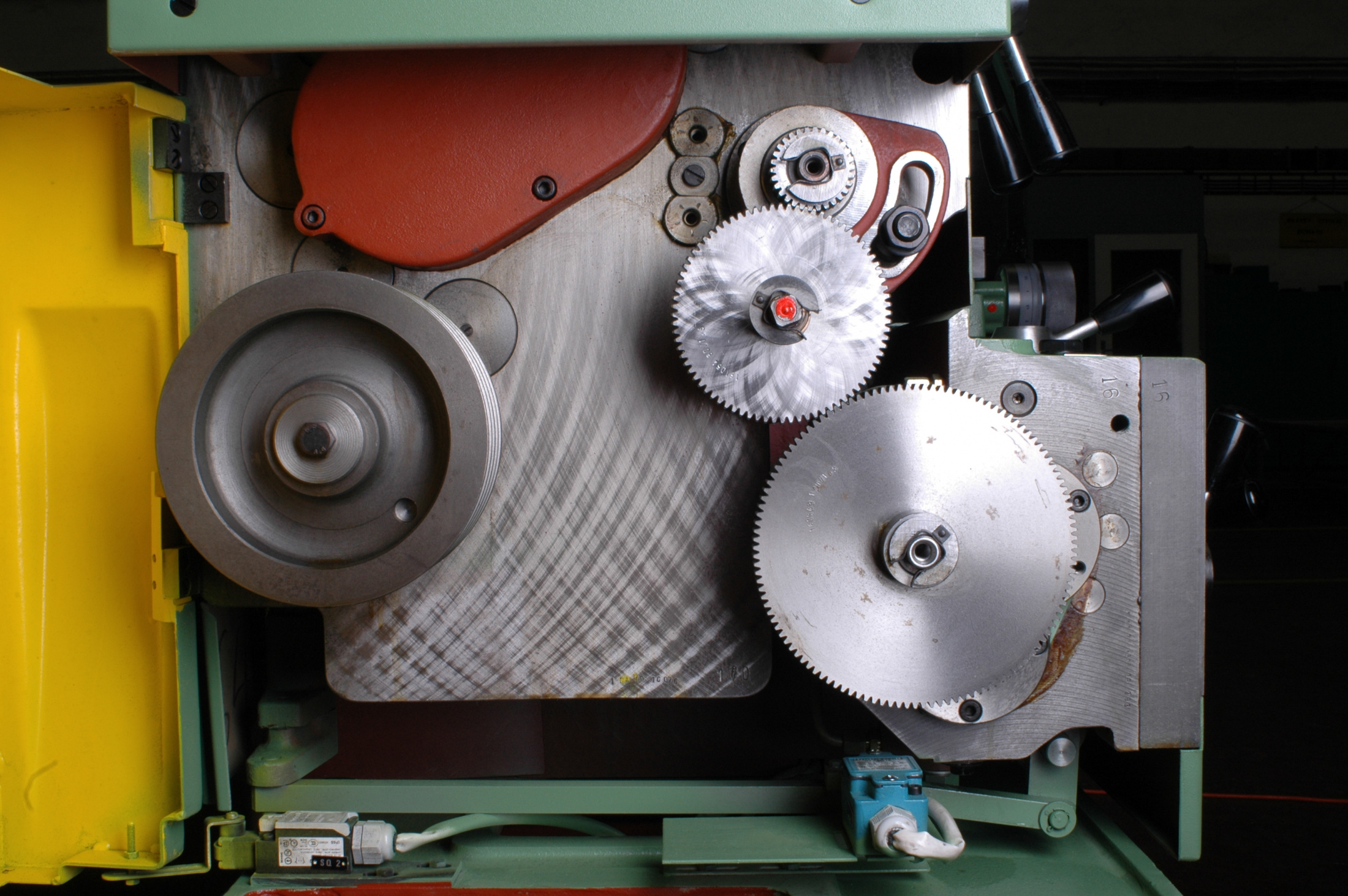

- Important parts of the machine are made of grey cast iron – minimization of generating vibrations throughout machining

- Hardened bed guide ways – long lifetime and constant accuracy of machining

- Hand scrapping of the important parts – high precision during machining

- Bed gap for increasing the swing and delta-shape bed – high resistance against deformation and continuous chip conveyance

- Spindle drive through clutches and brake – smooth movement stop

- Single lever for four way control of feeds with adjustable feed clutches

Main advantages

- Easy maintenance

- Long lifetime

- Low operating costs

- Simple and ergonomic control

- High turning precision

- Possibility to cut all types of threads with wide range of pitches

- Wide range of optional accessories – digital read-outs, quick-change tool posts, steady and follow rests, rolling contact bearings for steadies, micrometric stops, taper turning attachments, faceplates and chucks

English

English Slovenčina

Slovenčina French

French русский

русский Deutsch

Deutsch Türkçe

Türkçe العربية

العربية Chinese

Chinese