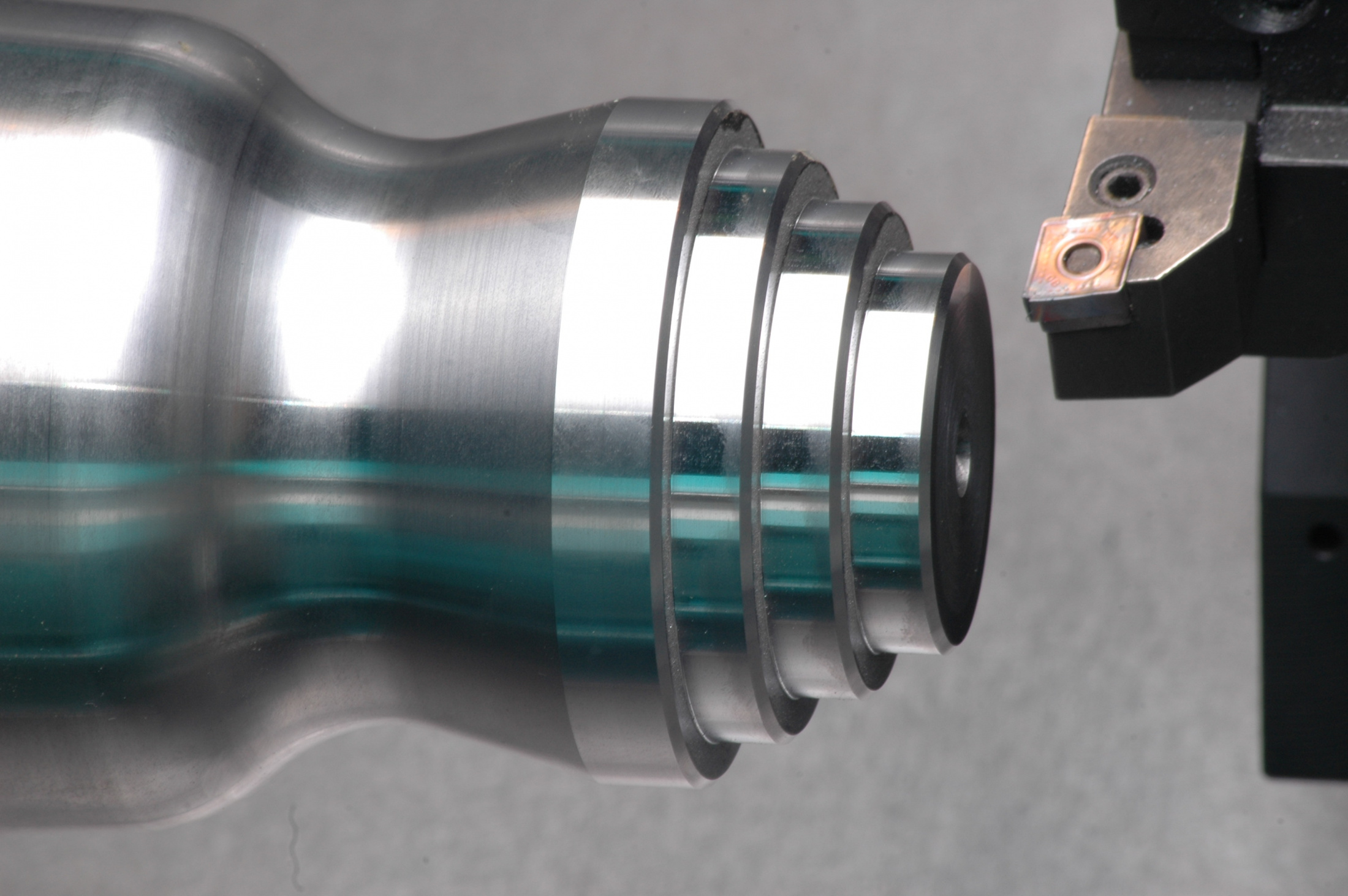

| Max swing diameter | 530 mm | |

| Max turning diameter | 260 mm | |

| Length of turning in chuck and tailstock | 500 mm | |

| Max diameter of bars | 42*/51/74* mm | |

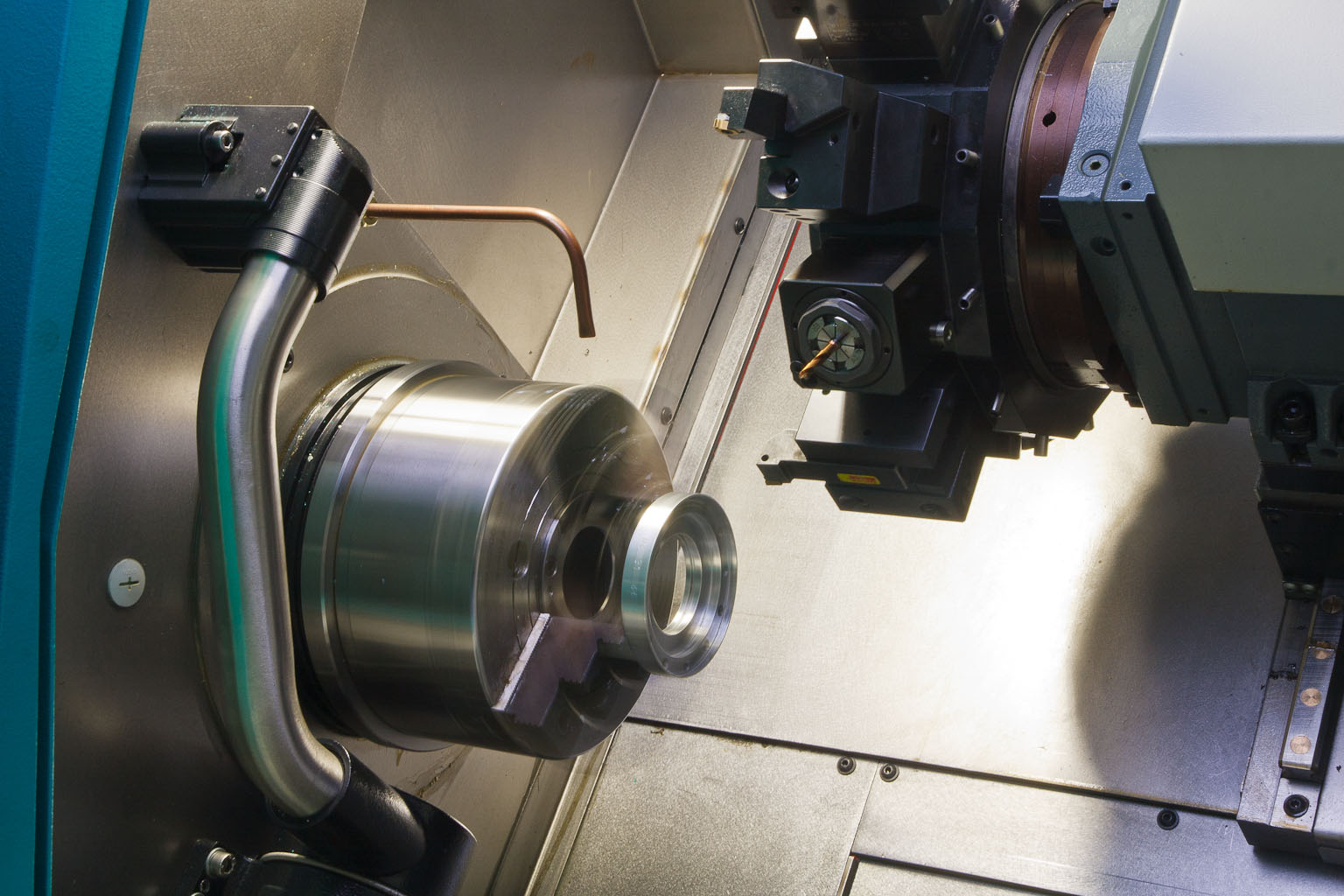

| Max weight of workpiece in centers | 200 kg | |

| Max weight of overhung workpiece | 80 kg |

* valid for optional execution

https://www.trens.sk/sites/default/files/01_katalog_aj_small_51.pdf

https://www.trens.sk/sites/default/files/tech_list_sbl300_bez_3.pdf

Description

Machine designed for medium to large-series production for machining simple and complex shape workpieces.

This machine significantly contributes to increased productivity while considerably decreasing investment costs.

Main characteristic features:

- Modular concept of the machine allows confi guration tailored to the customer´s individual requirements.

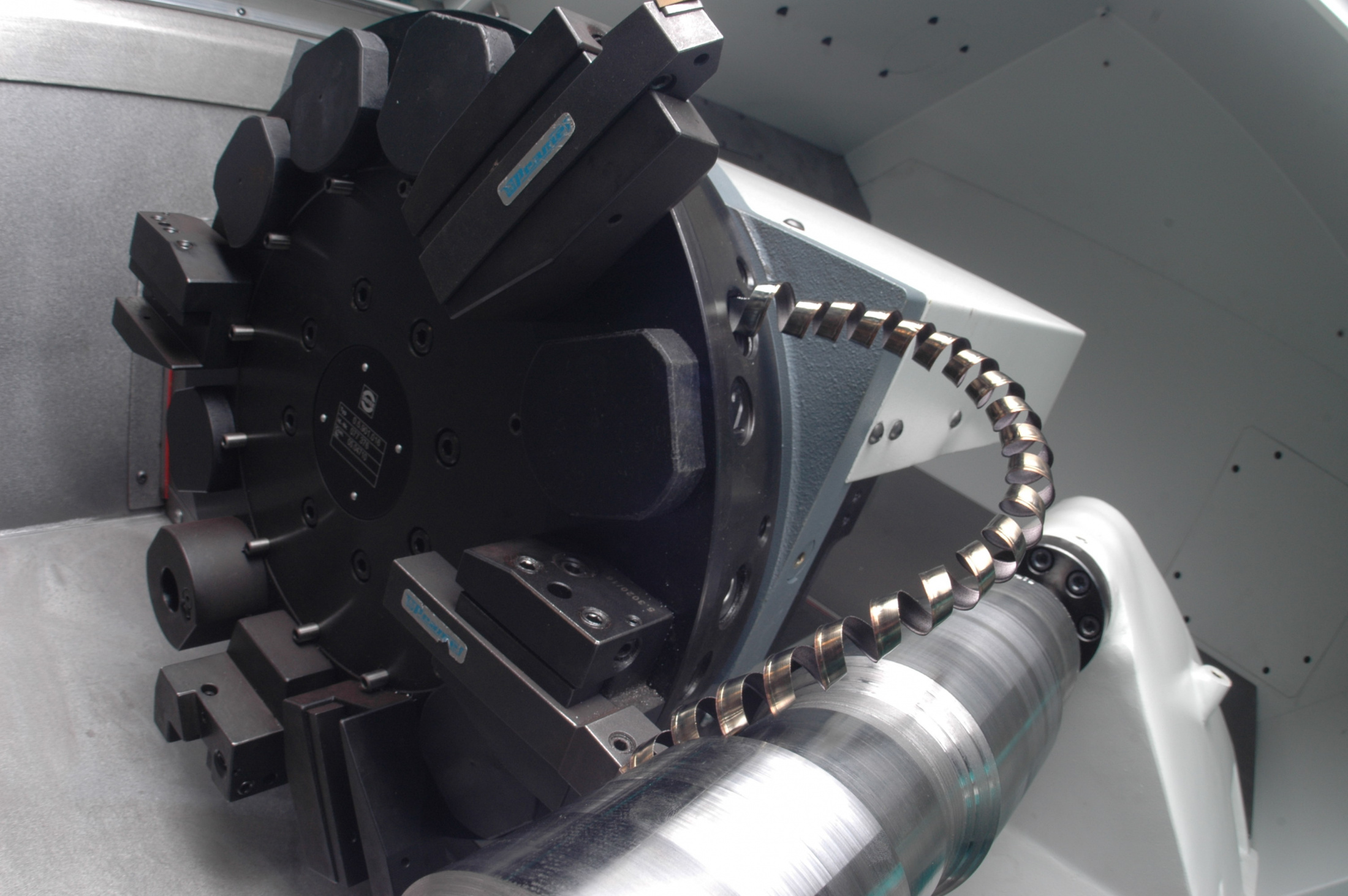

- 12 position turret with VDI 30 couplings without live tools

- Remote diagnostics and data management

- Wide range of executions and accessories – hydraulic clamping with chucks or collets, bar feeders, tool probes, parts catchers, automatic door opening, work area vapour exhaust

| Tool post systems | ||

| 12-position axial turret | ||

| Number of positions | 12 | |

| Tool shank diameter (according to DIN 69880) | mm | 30 |

| Max. tool cross-section | mm | 20x16 |

Characteristic features

Productive CNC lathes of a rigid construction with slant bed designed for high precision and productive machining in challenging conditions of multi-shift operation.

- Variable building kit based on monolithic slant bed of cast iron – high rigidity and accuracy of the machine

- Quality components from renowned producers – long lifetime and long reliability while preserving repeatable accuracy of the machine

- Production of strategic components in own premises with continuous checking and accuracy evaluation at 3D measuring devices

- X-axis measuring by linear scale as a standard – increased machining accuracy

- Grease lubrication – lowering the environmental impact

- No-attendance automated mode with feeders and part catchers – lowering production costs

Main advantages

- High precision and productive machining of simple as well as complex shape workpieces

- Steady cutting process with high repeatable accuracy of machining

- Remote diagnostics and data management

- Modular concept of the machine allows configuration tailored to the technological needs of production

- Variety of turrets with VDI couplings without live tool drive

- Wide scope of executions and accessories – clamping devices, bar feeders, part catchers, tool probes, automatic door opening, vapour exhaust system

- Newest technologies in the field of drives bring savings in electric energy

English

English Slovenčina

Slovenčina French

French русский

русский Deutsch

Deutsch Türkçe

Türkçe العربية

العربية Chinese

Chinese