| Max swing diameter | 650 mm | |

| Max turning diameter | 550 mm | |

| Max bar diameter | 74/117* mm | |

| Max diameter of bars with spindle reduction sleeve or with spindle prolongation | 66/103* mm | |

| Max weight of workpiece in centers | 1000 kg | |

| Max weight of overhung workpiece | 372 kg |

*valid for optional execution

https://www.trens.sk/sites/default/files/01_katalog_aj_small_121.pdf

https://www.trens.sk/sites/default/files/tech_list_sbx500_bez_9.pdf

Description

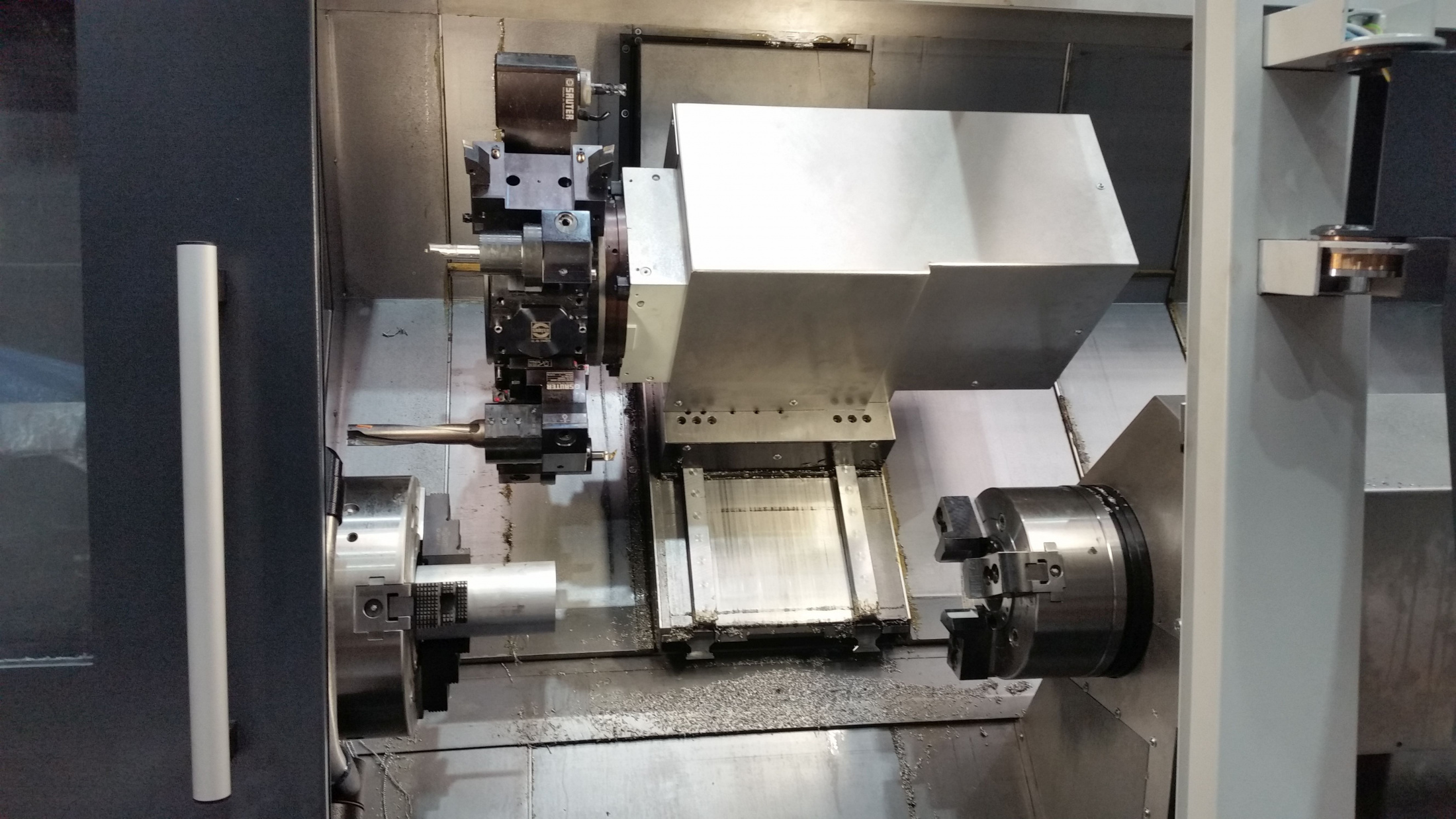

High productivity turning center of a rigid design suitable for medium to large production of simple as well as complex geometrical shapes. Machine execution with Y-axis and live tools allows machinig of complex shape workpieces on a single machine which significantly reduces production time and increases workpiece accuracy.

Machine seriously contributes to increased productivity while decreases investment costs.

Main characteristic features

- Modular conception allows configuring the machine for wide range of technologies and materials

- Y axis with saddle wedge contributes to increased stability of cutting process

- Fast turret with 12 live tools size VDI 40

- C-axis with independent servomotor for achieving precise and stabile work piece position during cutting forces loading

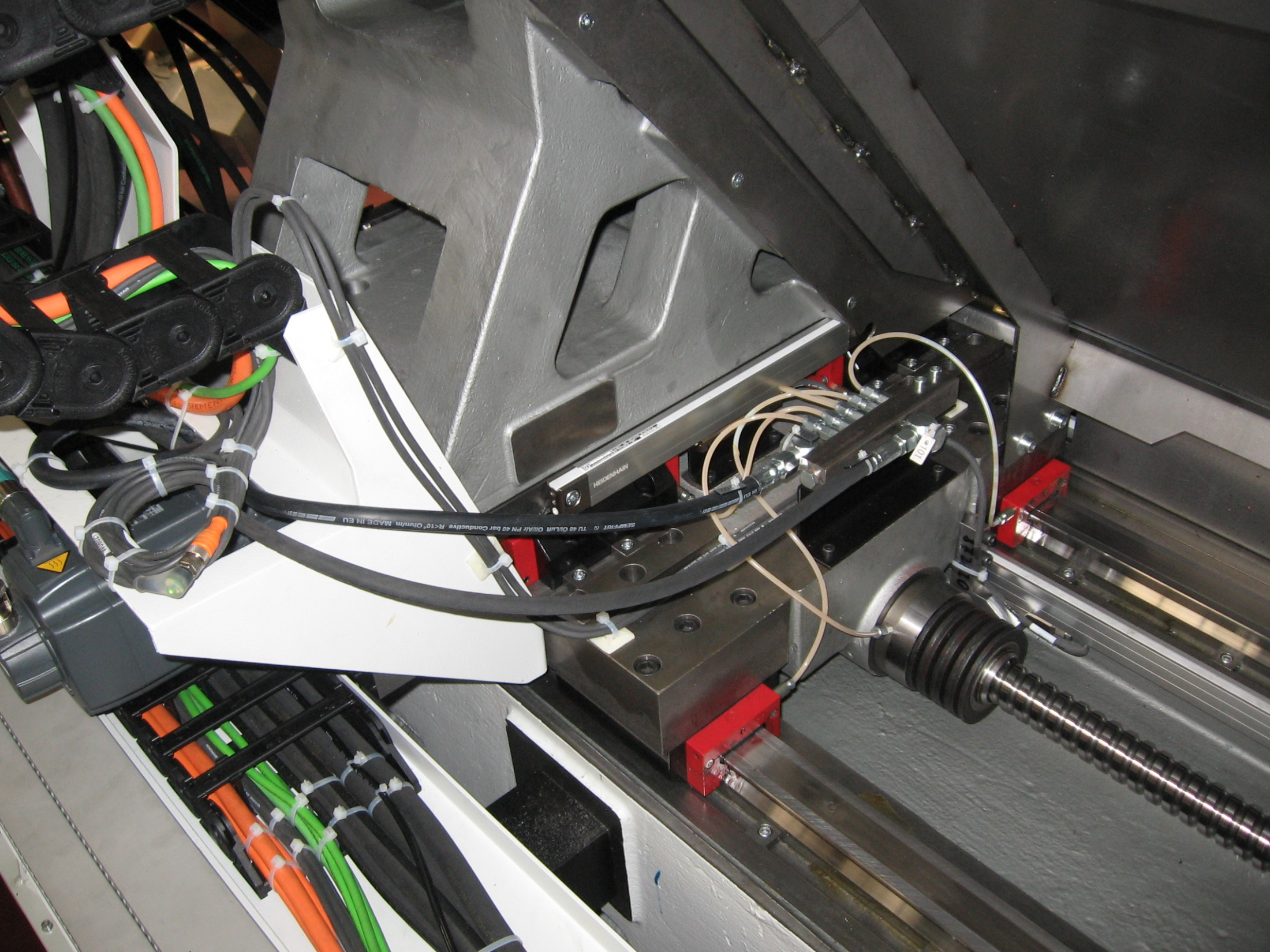

- Linear roller guide ways with bearing capacity dimensioned for hard roughing but also precision of finishing operations

- Increased spindle bores extend the machining possibilities for wider assortment of work pieces

- Integrated control panel improves machine control ergonomics for operator

- Programming in 3D through cycles

- Technology of servo drives with electric energy saving

- Option of industrial robot integration for manipulation of raw material and work pieces

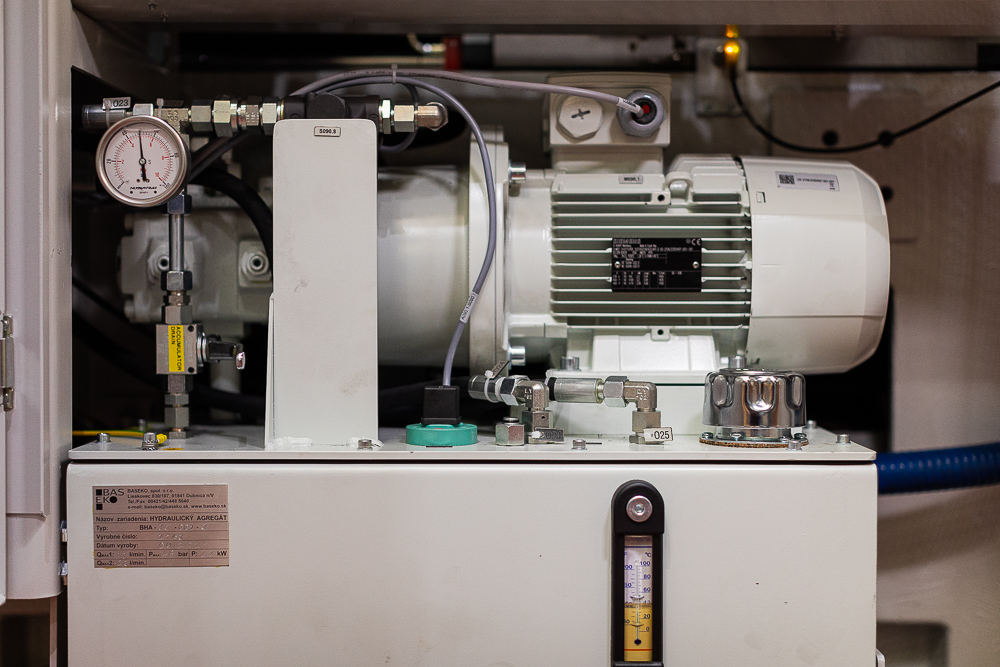

- Coolant aggregate with pressure from 0.7 MPa (7 bar) up to 2.0 MPa (20 bar)

| Carriages and drives | ||

| X-axis | ||

| Operating feed | mm.min -1 | 1÷10000 |

| Rapid traverse of cross-slide | mm.min -1 | 24 000 |

| Operating stroke | mm | 300 |

| Y-axis | ||

| Operating feed of Y-axis | mm.min -1 | 1÷10000 |

| Rapid traverse of Y-axis | mm.min -1 | 24 000 |

| Operating stroke of Y-axis | mm | +/-60 |

| C-axis with separate servo motor (heavy duty) | ||

| Continuous control | ° | 0-360 po 0,001 |

| Max. spindle speed | min -1 | 50/45* |

| Torque S1 | Nm | 337/380* |

| Z-axis | ||

| Operating feed of longitudinal slide | mm.min -1 | 1÷10000 |

| Rapid traverse of longitudinal slide | mm.min -1 | 30 000 |

| Operating stroke | mm | 905/1655* |

| Tool post systems | ||

| 12-position axial turret with live tool positions | ||

| Number of positions | 12 | |

| Number of driven tool positions | 12 | |

| Tool shank diameter (according to DIN 69880) | mm | 40 |

| Coupling | 20x0,8, DIN 5480 | |

| Max. tool cross-section | mm | 25x25 |

| Driven tools motor output | kW | 10 |

| Max. torque | Nm | 63 |

| Max. RPM | min -1 | 4 000 |

Characteristic features

Productive turning centers of a rigid construction with slant bed designed for high precision and productive machining in challenging conditions of multi-shift operation.

- Variable building kit based on monolithic slant bed of cast iron – high rigidity and accuracy of the machine

- Quality components from renowned producers – long lifetime and long reliability while preserving repeatable accuracy of the machine

- Production of strategic components in own premises with continuous checking and accuracy evaluation at 3D measuring devices

- X-axis measuring by linear scale as a standard – increased machining accuracy

- Grease lubrication – lowering the environmental impact

- No-attendance automated mode with feeders and part catchers – lowering production costs

Main advantages

- High precision and productive machining of simple as well as complex shape workpieces

- Steady cutting process with high repeatable accuracy of machining

- Remote diagnostics and data management

- Modular concept of the machine allows configuration tailored to the technological needs of production

- Variety of turrets with VDI couplings with live tool drive

- Wide scope of executions and accessories – clamping devices, bar feeders, part catchers, tool probes, automatic door opening, vapour exhaust system

- Newest technologies in the field of drives bring savings in electric energy

English

English Slovenčina

Slovenčina French

French русский

русский Deutsch

Deutsch Türkçe

Türkçe العربية

العربية Chinese

Chinese